Progressive Die Design - Overview

Dedicated software for the design of Progressive Dies and Press Tools providing a more productive and efficient design experience by helping the designer with intelligent decisions, reducing the potential for error and greatly improving manufacturing productivity.

Sheet Metal Springback Compensation

The Advanced Modelling module of VISI is used to apply springback to a complex automotive sheet metal component based upon the original CAD model and the result of a light scan

Springback compensation from 3D curves

The Advanced Modelling module of VISI is used to apply springback to a complex automotive sheet metal component based upon the original CAD model section curves that define the overbend value

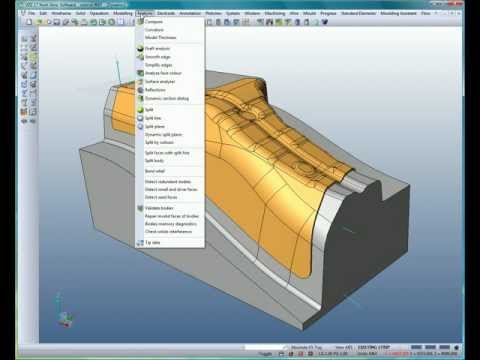

Die block construction

Construction of a die block from source CAD model using a combination of solid & surface techniques. This movie shows skin extraction, trim edits, tangential surface extension, fillet creation and boolean operations to close to a solid model.

VISI PEPS Wire EDM

Developed specifically for the precision engineering, tool-making, mould & die, press and extrusion tool industries, VISI PEPS-Wire provides automatic feature recognition of wire features including tapered, variable taper and 4 axis directly from solid geometry creating reliable and proven NC code for all machine tools.

VISI Progress - 3D Flange Unfolding

Step by Step unfolding allows the designer to plan each forming stage by dynamically adjusting bend angles. Flexible editing allows the removal or addition of extra stages providing the user with complete freedom for unfolding experimentation.