VISI software for mould design

VISI is acknowledged as one of the world's CAD / CAM software solutions for the Mould & Die industries. It offers a unique combination of surface and solid modelling, 3D tool design, comprehensive 2D, 3D and 5-Axis machining & Wire EDM

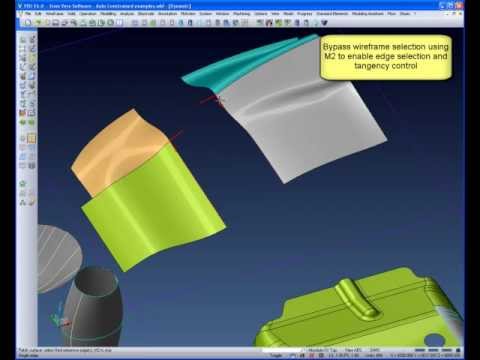

CADCAM - Core & Cavity Splitting

Automated core & cavity construction from a solid CAD model, including shut off building using a combination of surface and solid modelling techniques

Complex Core and Cavity construction for an automotive front console

Advanced core and cavity construction using a combination of surface and solid modelling techniques. This movie also shows model validation for draft analysis, part splitting, surface extension, parting face and shut off construction.

Mould design - Electrode extraction - Plastic flow analysis

VISI Mould provides the complete mould tool design solution based on industry specific automation that guides the user through the mould development process. Dynamic operation previews provide the designer with a 'real time' view of how component changes will affect the tool design.

All areas of moulded component creation can benefit from the optimisation of mould tool design and moulding process parameters. Part designers, mould makers and moulders will all benefit from using Vero's patented technology for injection simulation to achieve cost effective and reliable mould designs and the optimum moulding conditions. VISI Flow is a unique prediction tool, ideal for pre and post production analysis and concurrent engineering of injection moulded plastic components.

VISI Electrode is an automated module for the creation and management of electrodes and their holders for the manufacture of detailed and hard to machine features on mould and press tools. Comprehensive holder design, simulation and collision checking ensures that the electrode will operate right first time.

Plastic flow analysis - Integrated CAD - CAM - CAE from Vero Software

All areas of moulded component creation can benefit from the optimisation of mould tool design and moulding process parameters. Part designers, mould makers and moulders will all benefit from using Vero's innovative technology for injection simulation to achieve cost effective and reliable mould designs and the optimum moulding conditions.

Assembly Tool Manager

VISI is able to manage mould tool assembly attributes based on user-defined layer structures or standard component relationships. Part list information is automatically created and can be exported as an external spreadsheet for downstream processes such as detailing and stock ordering.

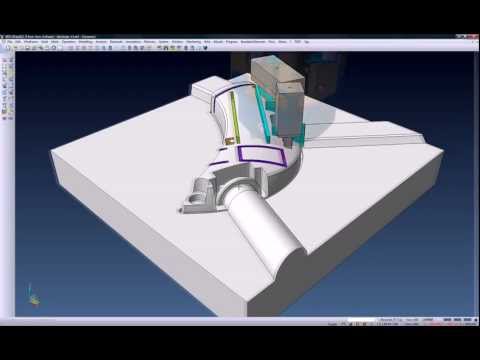

Electrode construction

VISI Electrode is an automated module for the creation and management of electrodes and their holders for the manufacture of detailed and hard to machine features on mould and press tools. Comprehensive holder design, simulation and collision checking ensures that the electrode will operate right first time.

EDM electrode creation can be one of the most complex and time consuming projects for any mould or die maker. The VISI suite of products offer a solution at every point of the manufacturing process from design to manufacture. Even the most experienced electrode designer will benefit from the knowledge based automation provided by VISI Electrode.

VISI PEPS Wire EDM

Developed specifically for the precision engineering, tool-making, mould & die, press and extrusion tool industries, VISI PEPS-Wire provides automatic feature recognition of wire features including tapered, variable taper and 4 axis directly from solid geometry creating reliable and proven NC code for all machine tools.

Surface Hole Filling

When preparing data for manufacture it is often necessary to fill gaps on the original model. In a solid environment it is possible to dynamically edit the model. However, with complex 3D forms this task often requires high level surfacing.

Interactive Model Editing

VISI Modelling utilises the industry standard Parasolid® kernel and provides tools to dynamically edit solid models by moving / deleting features, editing fillet radii, adding draft and moving faces all without the need to edit parametric constraints or use surface techniques.

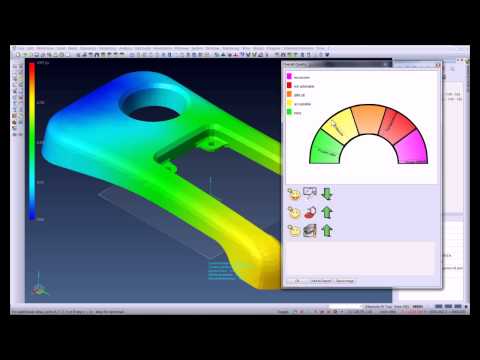

Model Thickness Analysis

A very important application for the moulding industry. This tool graphically displays the model thickness using multiple algorithms providing valuable information for potential moulding issues such as material accumulation, gating positions, rib criteria and cooling channel locations.

Core & Cavity Construction

VISI Modelling is the foundation of all VISI products and provides a robust and powerful solid and surface modelling system based around the industry standard Parasolid® kernel. Combined with Vero's surface technology, model analysis and 2D design, VISI Modelling offers complete flexibility to construct, edit or repair the most complex 3D data.