Automotive Core & Cavity creation - Step 1

Step 1 of the core & cavity construction process. The hole filling process uses a combination of tangential curve construction, surface editing and new surface building maintaining shape curvature.

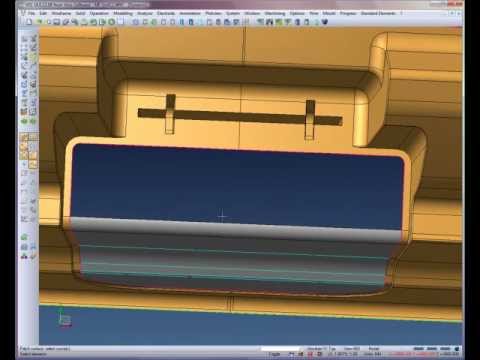

Automotive Core & Cavity creation - Step 2

Step 2 of the core & cavity construction process. The internal clip shut off is built using a combination of surface extrusions, tangential extensions, surface trimming and hole filling.

Automotive Core & Cavity creation - Step 3

Step 3 of the core & cavity construction process. Closing off the internal holes using a combination of automated hole filling techniques, surface trimming and drape surfaces.

Automotive Core & Cavity creation - Step 4

Step 4 of the core & cavity construction process. Complex shut off with surface extraction, curve concatenation and 3D offset, draft surface from edges, fillet construction and surface trimming.

Automotive Core & Cavity creation - Step 5

Step 5 of the core & cavity construction process. Building parting faces with tangential face extension, surface extrusions, 3D curve construction, drape surfacing and surface trimming.